3D printing

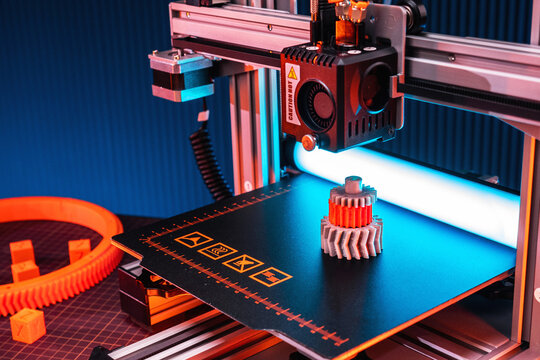

3D printing can help to visualize and analyze your digital designs in a real prototype model.

3D printing can provide great savings on assembly costs because it can print already assembled products.

With 3D printing, companies can now experiment with new ideas and numerous design iterations with no extensive time or tooling expense. They can decide if product concepts are worth to allocate additional resources.

Aplications

Electronic, Aerospace, Prototypes, Fixtures, Tooling, Medical, and more.

End-use Parts

Our 3D printers allow you to create and print functional end-use parts directly from your desktop or office. Attain custom parts with fine feature details and exceptionally smooth surfaces with the click of a button and begin directing your new product design, packaging or tooling needs with precision and confidence. Yes, in addition to quick and accurate prototyping for visualization, testing, evaluation and communication, our machines and services enable streamlined end use production for more efficient and affordable design-to-manufacture solutions.

Injection Molding

Injection molding is still the preferred process for manufacturing plastic parts in larger volumes, which is why it is used to create things such as housings, containers, bottle caps, combs and other mass market applications. One of the reasons injection molding is ideal for producing high volumes of plastic parts is because several parts can be produced in each cycle by using multi-cavity injection molds. Other advantages include high tolerance precision, repeatability and a large material selection.

Aerospace & Defense

Once relied upon for prototyping, design verification and testing, 3D Systems’ machines now print functional, end-use aerospace and defense parts. Our printers’ materials and build capabilities have reduced aerospace part number and weight while improving overall efficiency in meaningful and measurable ways, unattainable through traditional manufacturing methods. And the ability to print replacement parts on-demand rather than filling expensive and limited space with inventory? It’s no small wonder our technology is taking flight.

Automotive

For over 20 years, 3D Systems has accelerated vehicle design with its professional and production additive manufacturing systems and services. Our 3D printers have enabled our design and engineering customers to produce functional and durable parts with efficiency-improving build complexities that are unachievable through traditional means, in addition to giving them bridge- and direct manufacturing capabilities. Whether the need is to improve fuel economy, optimize part count to weight ratios, or eliminate tooling costs, our ability to put automotive and transportation specialists on the fast track to success revs both our engine and theirs.

Materials

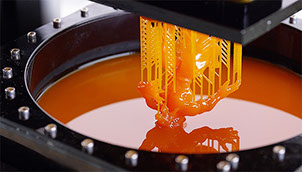

Resin

Types of Resins.

1. Standard: create accurate and robust parts, ideal for rapid prototyping and product development. Surface finish: Perfectly smooth right out of the printer.

2. Tough: Sturdy prototypes that will deform under pressure where other 3D prints fail. Responsive: Parts that absorb force; flexing and returning to form. Rugged: Prints that can tolerate mechanical friction and strain.

3. Castable: Tiny details like prongs line up so you can set stones with confidence.

4. Flexible: Its compression characteristics make this impact-resistant resin ideal for custom gaskets, grips, and flexible joints. Surface Finish: Smooth finish perfect for tactile interfaces, wearables, and prototyping.

5. Dental: Design surgical guides by using implant treatment planning software to integrate CBCT and intraoral scan data. Simply sterilize prints in an autoclave to use surgical guides directly in the mouth during implant surgery.

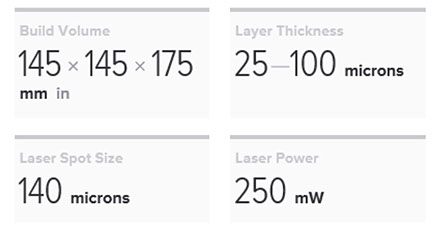

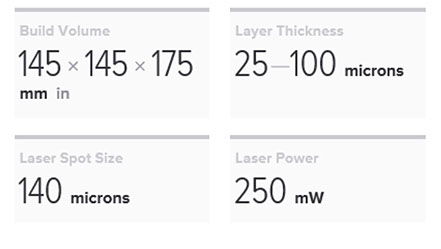

Resin Process (Specifications)

Layer Thickness (Axis Resolution)

25, 50, 100 microns

0.001, 0.002, 0.004 inches

Laser Spot Size (FWHM)

140 microns

0.0055 inches

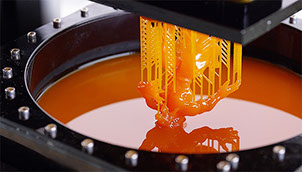

Resin Process

Engineered for precision.

Designed for reliability. A new peel mechanism and heated resin tank create a reliable print process for large, solid parts and small intricate details.

Slide Peel. Print big, solid parts with lower peel forces and reduced wear on the resin tank.

Resin Wiper. Improve print consistency by removing any particulates from the build area, properly agitating the resin.

Heated tank. Achieve optimal print conditions by maintaining a consistent internal temperature of 35 °C.

Automated

Resin System. The Form 2 prints bigger, better. Our new integrated resin system allows for larger prints, less mess, and longer tank life.

Level Sensing. Ensures your tank is automatically filled during printing, no more pausing for manual top ups.

Cartridge ID Chip. Allows you to keep track of resin supplies from your dashboard.

Open Mode. Lets you continue to experiment with 3rd party resins.

FILAMENT

Types of Filaments.

1. Nylon: Print stronger, flexible and long lasting prints with Nylon. This is an engineering-grade performance material, designed for powerful printing in the lab and workshop. Strength, flexibility and durability enable unparalleled prints. Nylon material is a staple material for functional prototyping and testing for engineers, designers, small business and startups.

2. PLA/ABS: PLA has excellent dimensional stability properties and ABS is a durable, high impact material.

3. Infinity Rinse-Away support material: Break beyond the boundaries set by unachievable overhangs and the laws of gravity, and enter the possibilities of intricate design, degrees of freedom and suspension in space. Ability to print with movement and articulation in one print.

4. SCAN PROCESS.

Resin Process (Specifications)

Filament Process (Specifications)

Z Axis resolution

All models

0.100mm (0.004″ / 100 microns)

Layer thickness

All models

70 microns, 200 microns and 300 microns for fast mode. Available for all three models.

Filament Process

Controlled print environment

A controlled process environment ensures improved accuracy and reliability of print for effortless, professional quality every time for your largest ABS plastic prints. Automated settings ensure home-safe printing in your mancave, on your workbench and at your desktop.

Print big, print accurate

The CubePro features the largest-in-class build platform with ultra high-resolution. With prints 2.5 times larger than any other desktop prosumer and hobbyist printer (11.2″ x 10.6″ x 9.06″ or 285.4mm x 270.4mm x 230mm) with ultra high-resolution settings of 70-micron thin print layers, professional quality printing has never been so large or easy.

New materials, limitless possibilities

Printing with complexity has never been easier. Break beyond boundaries set by unachievable overhangs and the laws of gravity, and enter the possibilities of intricate patters, degrees of freedom and suspension in space. Create functional prototype models or make end-use parts for your engineering applications.

Strong, fast & long-lasting

Guaranteed faster, more accurate prints with stabilized print mechanics and easy feed cartridges for prolonged material life.

Double color + Double materials = thousands of options

Get more expressive with 3D printing in up to 2 simultaneous colors with 2 material options. Select from over 24 vibrant colors for more unique combinations.

Location

Av. Francisco Javier Mina 23 Col. Mariano Abasolo, Mexicali, B.C., MX

info@naherco.com

Phone

Phone: (686) 120-4089

Phone: (686) 120-4089